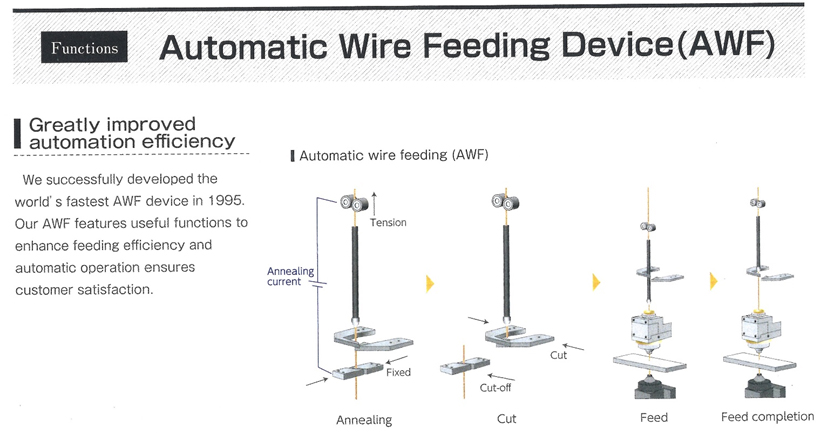

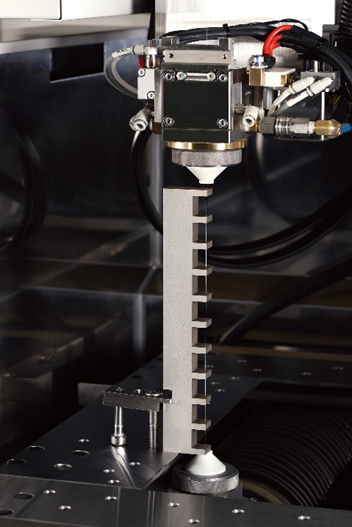

SEIBU developed the world fastest AWF device in 1995.

Picture at left is showing AWF capability to 17” long with 11 steps.

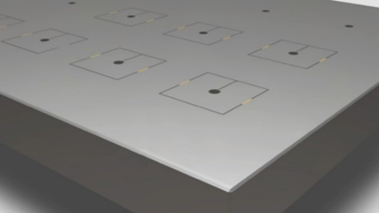

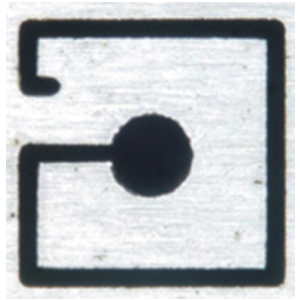

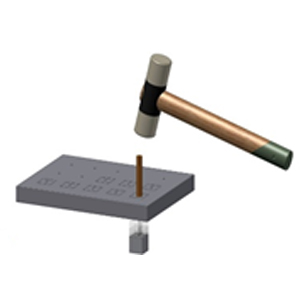

CORE STITCH (Patent)

ELIMINATING TAB BY CORE STITCH TECHNOLOGY

REMOVING THE CORE,

JUST TAP THE CORE PIECE.

START HOLE EDM DRILLING ATTACHMENT (Op)

EASY TO ATTACH TO THE MACHINE AND ALSO QUICK TO REMOVE.

Start hole drilling and EDM Wire cut without removing work pieces

from the machine table, slashing your cycle time drastically.

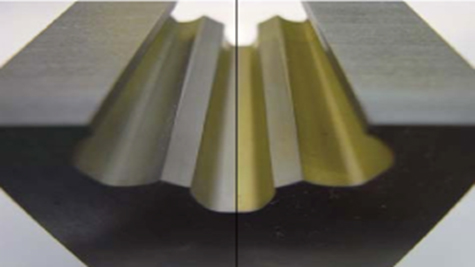

EL COATING (Patent)

SEIBU’s patented EL COATING provides automatic brass plating to the cutting surface utilizing cutting wire for plating while cutting work piece simultaneously.

This EL Coating provide less cobalt depletion while cutting Tungsten Carbide in the water which extend cutting tool life and provide better surface finish.

This feature will be effective for cutting tools like special insert for milling or turning cutters and also effective for punch press tooling made with Tungsten Carbide material.