Fryer MC Series: Designed for Exceptional Performance

MC Series - High Speed Machining Centers

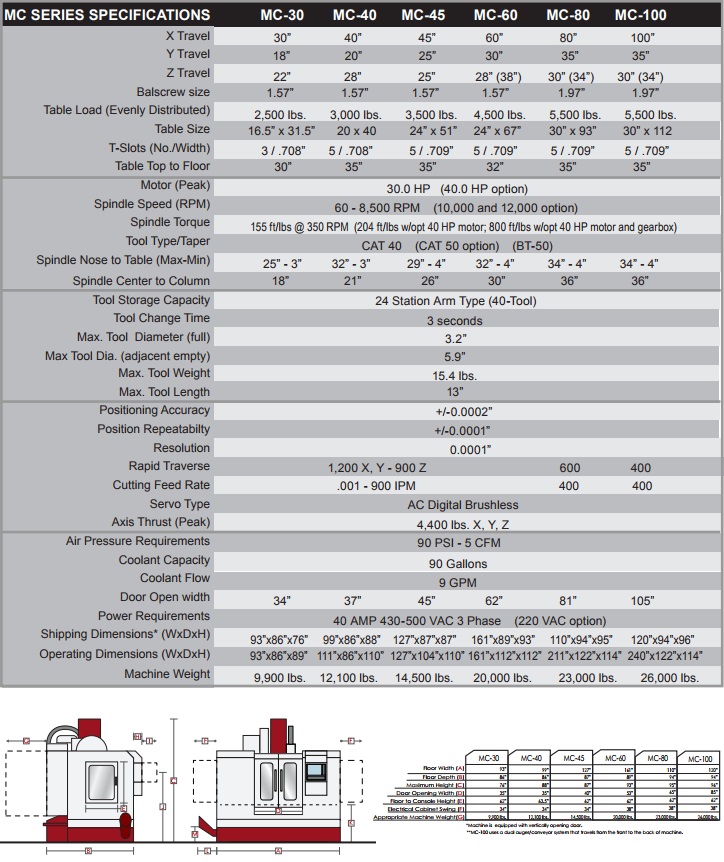

Fryer's MC Series offers exceptional performance by featuring heavyweight castings with box way construction. The standard 24-tool arm type ATC and 1,200 IPM rapids produce more parts per hour. Fully digital controls and drives combined with fast set-up and programming maximize performance and reliability.

MC-30 30" x 18" x 22"

MC-40 40" x 20" x 28"

MC-45 45" x 25" x 25"

MC-60 60" x 30" x 28" (optional Z 38")

MC-80 80" x 35" x 30" (optional Z 34")

MC-100 100" x 35" x 30" (optional Z 34")

Outstanding Features

- Box Way construction with Turcite B liners

- C3 grade double nut ball screws with class 7 bearings

- 1,200 IPM rapid feedrate

- 2,500 RPM rigid tapping

- 24-station arm type automatic tool changer

- Extra large 8,500 RPM CAT 40-spindle

- Early Power Failure Detection

- All axis laser calibrated & ballbar verified

- Hand built precision +/- .0002” entire travel

- High Speed all digital control system

- Absolute encoders - no homing required

- Siemens Solution Series motors and drives

- One year warranty

Optional Features

- Heidenhain glass scales

- 12,000 and 15,000 RPM spindles

- High speed machining

- 1,000 PSI thru-spindle coolant

- 50 taper spindle

- Expanded storage memory

- 4th axis rotary tables

- 5th axis trunion tables

- Chip conveyor system